We turn your plastic waste into high-quality furniture. Even if the plastic is not of the perfect quality or has a small contamination. This way, we save plastic that would otherwise go to waste. An example is our recent collaboration with Fairphone. During this project, we converted broken phone cases into a series of functional objects. The Delta is one of those objects. We designed it in collaboration with Studio Voronoi. The Delta is a multifunctional piece of furniture that can be used both as a stool and as a side table.

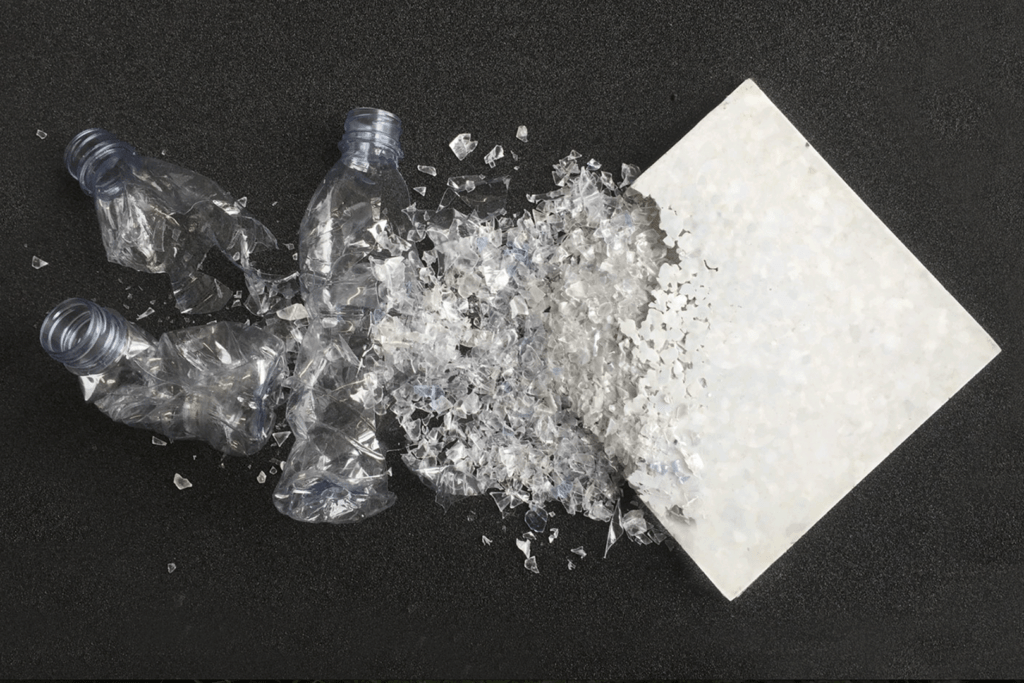

Nowadays, more and more people separate their plastic waste. Unfortunately, only a very small percentage of that plastic waste is recycled. Partly because of various complications that appear during the recycling process. Contamination of the plastic, for instance. Our 3D printer offers a solution to this problem. Due to the size of our 3D printer, we can print large objects. The large scale enables us to recycle plastic that would otherwise go to waste. For us, a small contamination in the plastic is no issue.

This is precisely the reason why Fairphone ended up at vanPlestik. The company had inquired about recycling their covers in various places. However, the metal logo that each case is provided with, always proved to be a problem. Fortunately, we did succeed in recycling the covers. It resulted in a series of functional objects. The origin of these new products is still clearly visible. The covers have taken on a completely different shape, but the recognizable colors have remained the same.

Back to where it all started, the objects have found a place at the Fairphone headquarters in Amsterdam. The fact that the company now has new objects from their own waste, ensures added value. In short: the circle is complete.

Want to get your hands on a Delta? Head over to our webshop.

HEMA announcing their collaboration with Too Good To Go

HEMA announcing their collaboration with Too Good To Go Reusable straws

Reusable straws Hema Support Office (image via

Hema Support Office (image via