This is how Fairphone is changing the smartphone industry from the inside out Creating fair(er) phones, that is Fairphone‘s mission. As Circular Innovation Lead, Miquel Ballester knows all about how to make an impact. We interviewed him about his role at Fairphone, ambitions and future plans. You have been with Fairphone pretty much from the […]

Upcycled waste bins for HEMA A product to create zero-waste headquarters Over the last year, we have been working on our biggest collaboration project yet. We are excited to finally share the results of our project for the retail chain HEMA. We designed and 3D printed almost 200 waste bins for their headquarters. Using old […]

Increasing the hygiene level during the Covid-19 crisis During the latest Coronavirus outbreak, measures and restrictions have been put into place to protect the population from getting infected. Among these are the requirements of wearing face masks, washing your hands regularly, and keeping the required distance. The outbreak also opened up a new market with […]

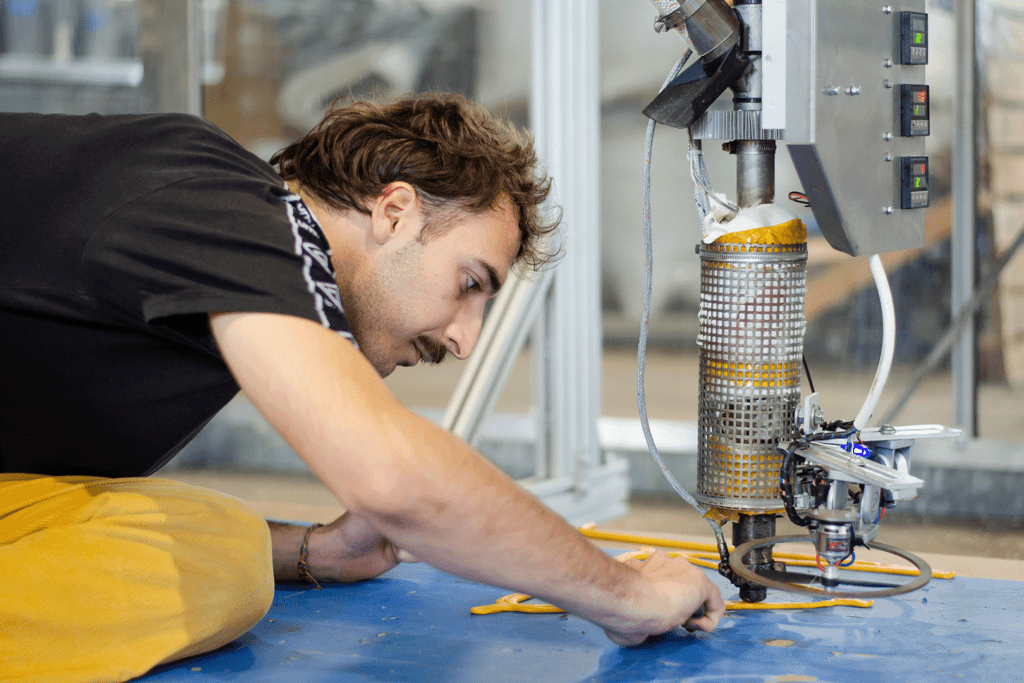

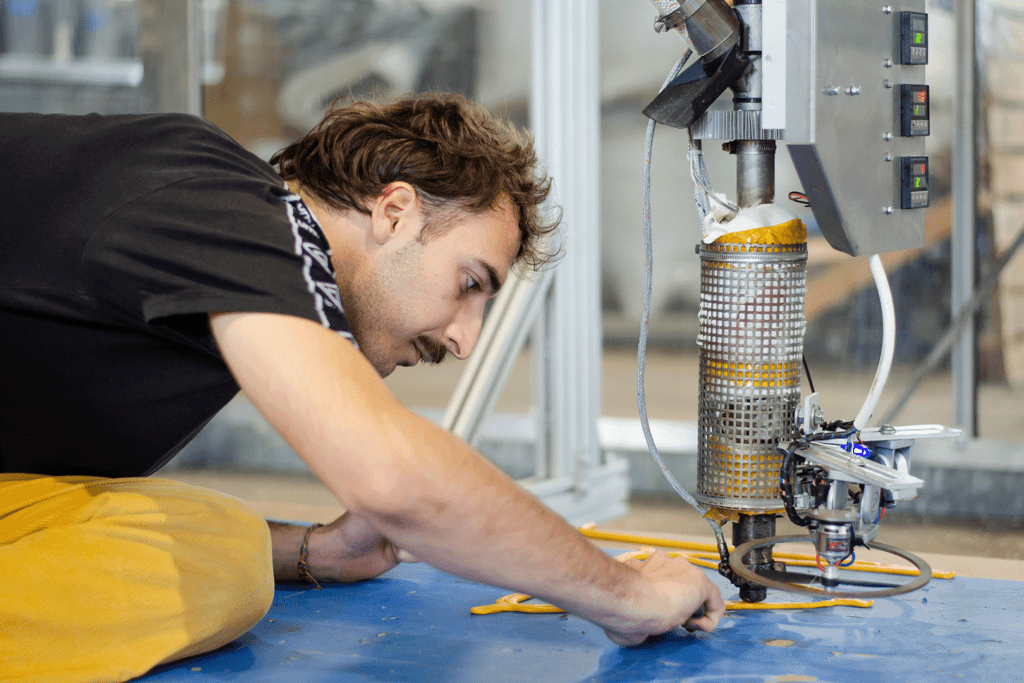

vanPlestik is looking for an ambitious designer who wants to contribute to our mission About the internship This internship is a combination of learning to work with our large 3D printers and designing your own product that you will produce yourself. The brief for the product is very open, so you will be able to […]

We turn your plastic waste into high-quality furniture. Even if the plastic is not of the perfect quality or has a small contamination. This way, we save plastic that would otherwise go to waste. An example is our recent collaboration with Fairphone. During this project, we converted broken phone cases into a series of functional […]

Just as no wave in the ocean is the same, every Wavy Table is unique in it’s shape. This side table made of packaging material, is created with a special technique. The Wavy Table is a so-called parametric design. It offers us the possibility to digitally adjust the design before printing. Sounds complicated? Let us […]

vanPlestik is looking for an enthusiastic content creator / media & communication intern with a talent for photography. During this internship you will work on external communication for various vanPlestik projects, in text as well as image. In a short period of time you will learn all about working in a small but ambitious company. […]

Recently we proudly presented our new collaboration partner: HEMA. This retailer has great ambitions in the field of sustainability. Earlier this year, HEMA announced to ban all single use plastics from their stores from 2020 onwards. How come sustainability is such an important topic for the company? And what can we expect in the future? […]

The power of one Often people think of environmental issues as too big to be able to make a difference as an individual. Artist Peter Smith is on a mission to change this mindset. We meet him in his workshop, where he tells us all about the philosophy behind his work: ‘the power of one’. The […]

3D printing a better future together We love to join forces with likeminded companies. This time we teamed up with sustainable product design studio, Better Future Factory. Alike us, they specialised in recycling waste and turning it into new products. Together, we created a series of objects for AVR – a company that converts residual […]