About vanPlestik

vanPlestik is a design studio and sustainable production company. We focus on recycling plastic waste that is difficult to process using traditional production methods. In order to recycle this plastic waste, we designed and built our own 3D-printers that use plastic waste as a raw material. Using these printers, we are able to locally recycle plastic into unique and valuable objects such as chairs, tables and lamps.

Mission and vision

vanPlestik is a company on a mission: creating beautiful circular products, raising awareness of the plastic problem and saving as much plastic as possible from incineration. We believe that the transition to a circular economy is a worldwide challenge that requires a combination of smart solutions. vanPlestik contributes to this by using large scale 3D printers to process plastic waste streams that are not currently recycled. By collaborating with companies and individuals, we are able to close the loop locally. We use our projects and products to show that plastic waste is a valuable material. In this way, we inspire others to contribute to the circular economy.

vanPlestik International

Eventually we want to spread the impact we make locally to a worldwide level. The lack of recycling facilities in many places causes plastic to end up in nature. With our cost effective 3D printers, we can offer a local solution to the plastic problem. This gives new companies the opportunity to also create valuable objects and prevent plastic from ending up in nature at the same time.

Would you like to know more about our approach, or do you want to help us to achieve our mission?

Our team

Nout Kooij

Founder

[email protected]

06-23925688

Nout is a designer, marketeer and plastic expert, and he likes to add some more jobs to that list. He is a real team player and loves to share the story of vanPlestik with anyone who wants to hear it.

Roos Bouman

Business Operations & Strategy

Roos is on maternity leave until November 2024

Roos makes sure everything runs smoothly. She is responsible for HR, finances, planning, project management, and is the first point of contact for most customers.

Harald den Breejen

3D-Printing Engineer

[email protected]

Harald is our printer-whisperer. He makes sure that our 3D-printers and production process are continuously developing. He adjusts our software, tests new materials and inspires us with innovative technical designs.

Robert-Willem Dol

Business Development & Partnerships

[email protected]

06-46641438

Robert-Willem is a true ambassador of vanPlestik. He loves to bring different parties together and is always on the lookout for new structural collaborations.

Interns

3D-printer & product design or Photography & Styling

We offer two internship positions for enthusiastic students who share our mission. Read more about these internships on our work with us page.

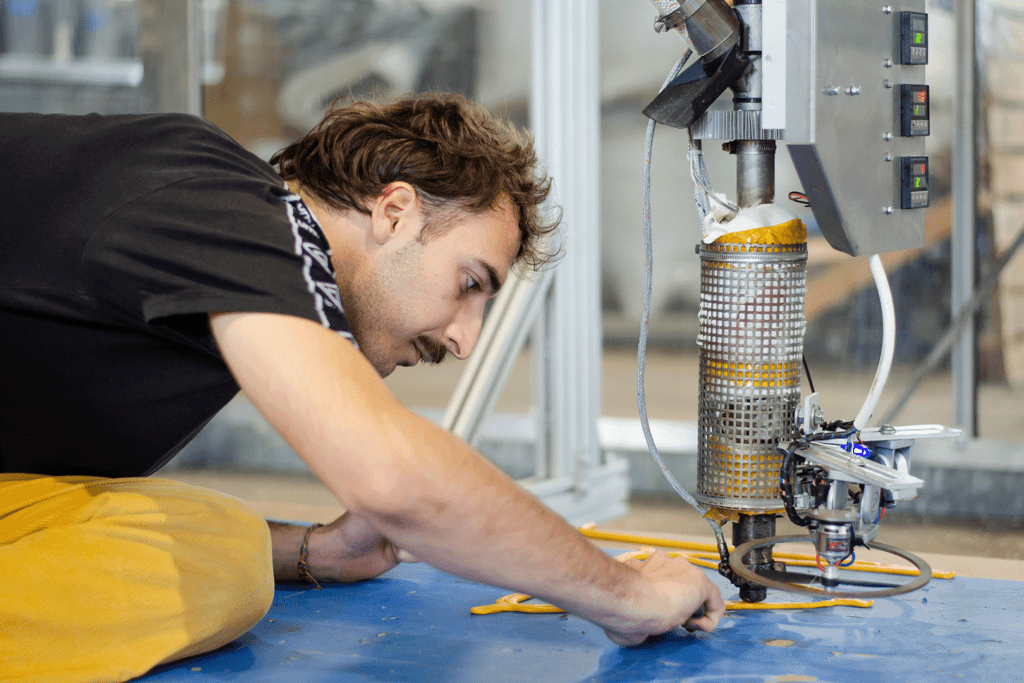

Our 3D-printers

Our 3D-printers are designed and built especially to be able to work with slightly contaminated plastic waste. In order to allow for any contamination in the material, we use quite a thick printline. This makes it relatively easy to produce large objects, but makes it more difficult to print small or very detailed products. The smallest dimensions for a product are 10x10x6 cm and the maximum size of a product is 450x130x90 cm.

Currently, we can process the following types of plastic:

- PS – Polystyrene

- PP – Polypropylene

- PC – Polycarbonate

- PETG

- ABS

- PLA

Contact

Do you want to know if we can recycle your plastic into a new and valuable product? Leave us a message, we are always open to discuss possibilities!