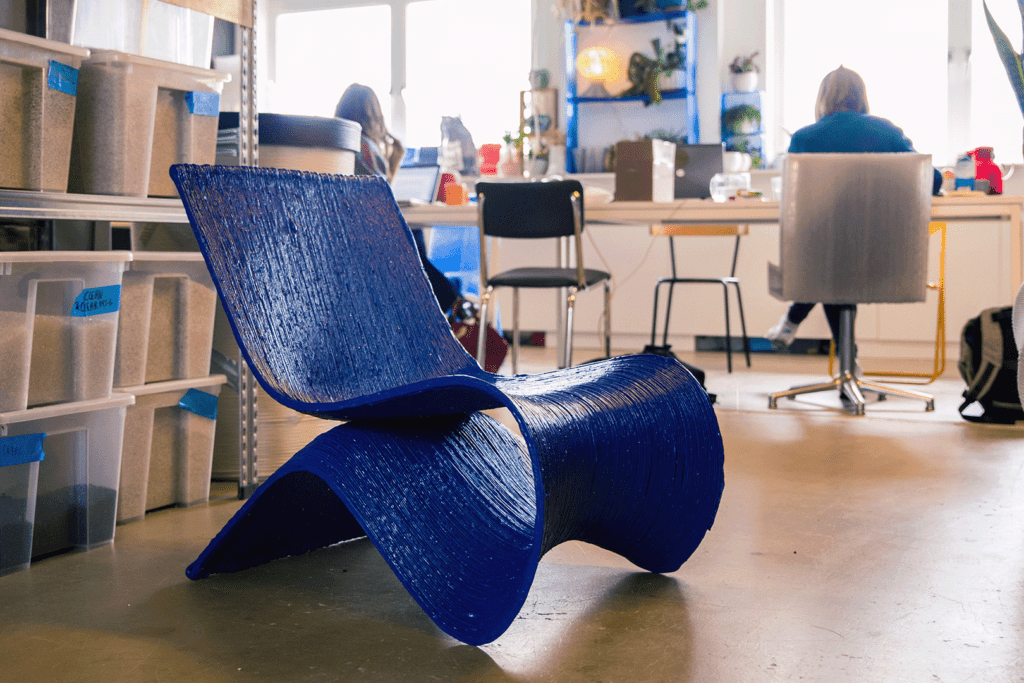

3D-printing of a complex shape

These positive chairs were made on assignment for Heldergroen and SoFoKleS, and will be placed in university hospitals in the Netherlands. Making a shape like this is difficult and therefore costly when using traditional techniques. But this is a perfect project for our 3D-printers!

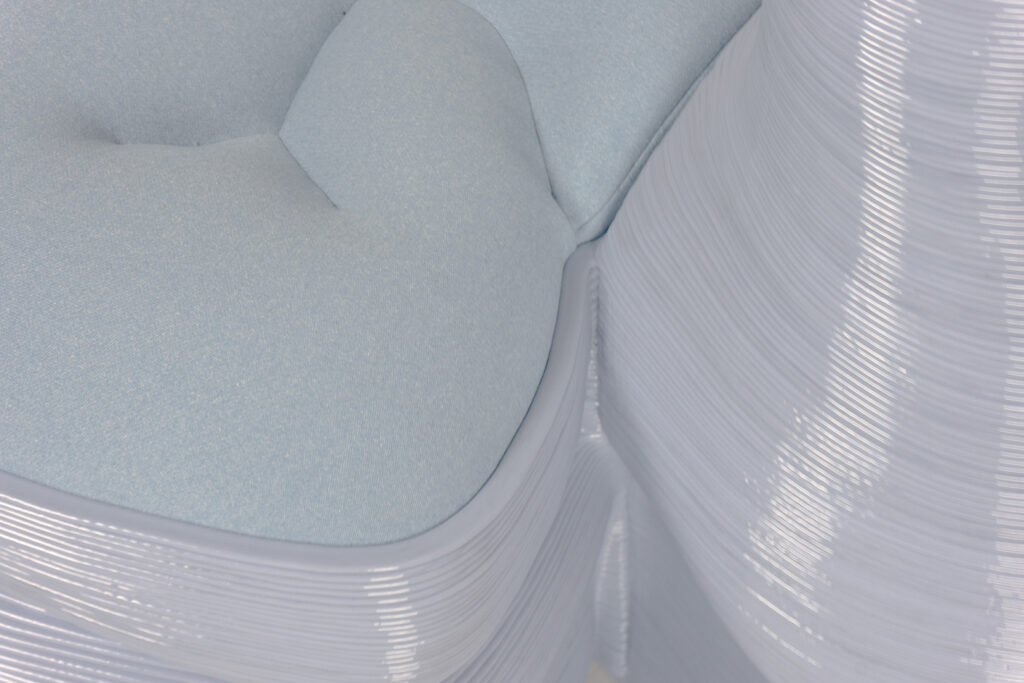

Plastic with a pillow

We used a pillow to create a comfortable chair and close the shape off completely. The cushioning is done by our partner Phranid, and is also made entirely from circular material. This chair is therefore made entirely from recycled materials, and is fully recyclable!

Do you have any questions about these chairs? Get in touch with us.