Just as no wave in the ocean is the same, every Wavy Table is unique in it’s shape. This side table made of packaging material, is created with a special technique. The Wavy Table is a so-called parametric design. It offers us the possibility to digitally adjust the design before printing. Sounds complicated? Let us take you through the process.

In an age of mass production, consumers seek something unique for their homes. The Wavy Table makes this possible in a very efficient way. Unlike various recycling methods, the start-up costs for a customized design are low. We can digitally adjust the parametric design to your wishes. Our 3D models are programmed with adaptable sliders. Every time we produce, we adjust the sliders. As a result, the 3D model changes and a different design is exported. In other words, no Wavy Table is the same.

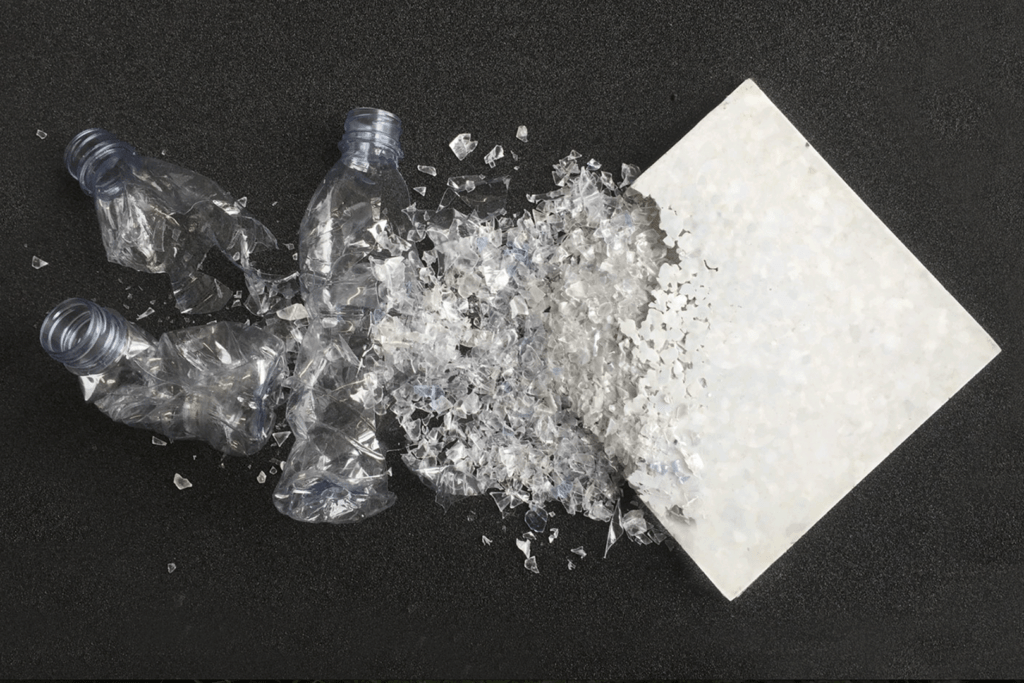

Not only is every Wavy Table unique, the design is completely circular. For example, let’s say after a number of years you’re fed up with your Wavy Table. No problem. We can get you a new design, using the same material. Simply return the Wavy Table to our workshop. From here, we reshred the material and print a brand new piece of furniture.

Want your own unique Wavy table? Click here to go to our webshop.

HEMA announcing their collaboration with Too Good To Go

HEMA announcing their collaboration with Too Good To Go Reusable straws

Reusable straws Hema Support Office (image via

Hema Support Office (image via